Unknown Facts About Roofing Boston

Roofing Boston Things To Know Before You Get This

Table of Contents10 Easy Facts About Roofing Boston ShownAll about Roofing Boston9 Easy Facts About Roofing Boston DescribedRoofing Boston - Questions5 Easy Facts About Roofing Boston Described

Polyisocyanurate insulation is inherently much more fireproof than polystyrene insulation. It always includes facers, which are thin sheets on both faces of the insulation, because facers are needed in the manufacturing process. Note that the foam insulation can compress and facers can flake when based on rush hour, for that reason a cover board is constantly suggested.There are 2 kinds of polystyrene insulation: broadened polystyrene (in some cases referred to as EPS or bead-board) as well as extruded polystyrene (often described as XPS). The 2 types have clearly various residential properties. Polystyrene is among the plastic foam insulations and also need to be used with caution where warm roof covering products are utilized.

If either of these is utilized, an appropriate cover board requires to be mounted over the EPS. EPS ought to not be utilized beneath a black membrane unless an appropriate cover board is installed in between the EPS as well as the membrane.

Nevertheless, boards intended for PMRs need to be especially produced for this application. Some small water absorption might happen in boards located above the membrane throughout the roofing system's life span. To make up the R-value reduction as a result of the water absorption, it is advised that the roof covering developer minimize the board's preliminary R-value by 10% - roofing Boston.

The 30-Second Trick For Roofing Boston

OSB and also fiberboard compounds are not suggested, as they do not stand up to incidental wetting. A nail-base insulation product must be examined to see to it it possesses ample compressive strength and also shear strength to stand up to the loads expected for the roof covering system. For aired vent nail-base insulation, the product must be examined to make certain the spacer material and also range in between spacer obstructs provides adequate compressive strength, as well as the bearing surface area of spacers provides sufficient shear strength.

With these boards, it is essential to mechanically connect the composite board as opposed to stick it. Otherwise the additional layer can easily remove. The developer must comprehend that joints in between the boards and the fasteners will stand for a path for thermal bridging, as a result composite insulation is recommended to be mounted over an underlying layer of non-composite insulation.

For all kinds of insulation, is advised to use multiple layers, with staggered joints. roofing Boston. Joints over 1/8" vast are typically filled with spray foam insulation, specifically if there is just one layer of insulation. Think about making use of optimum 4 by 4 foot boards to decrease the spaces brought on by shrinking of the insulation.

A Biased View of Roofing Boston

Blanket insulation is insulation that is supplied in a roll. Sprayed Polyurethane Foam Insulation Sprayed polyurethane foam (SPF) insulation systems are self-adhering, two-component products, that are used directly to roof covering decks, as well as may be used as an insulation and also air obstacle when related to the bottom of a roofing deck, or it may be used in mix with one of a number of kinds of protective layers as the primary roofing covering.

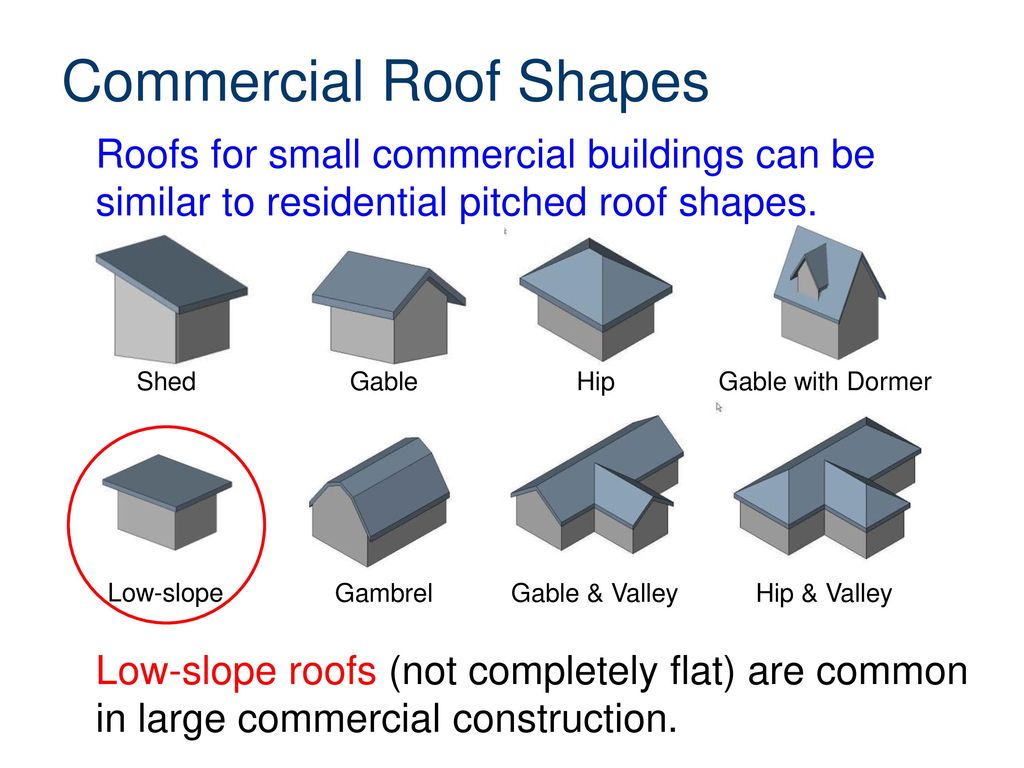

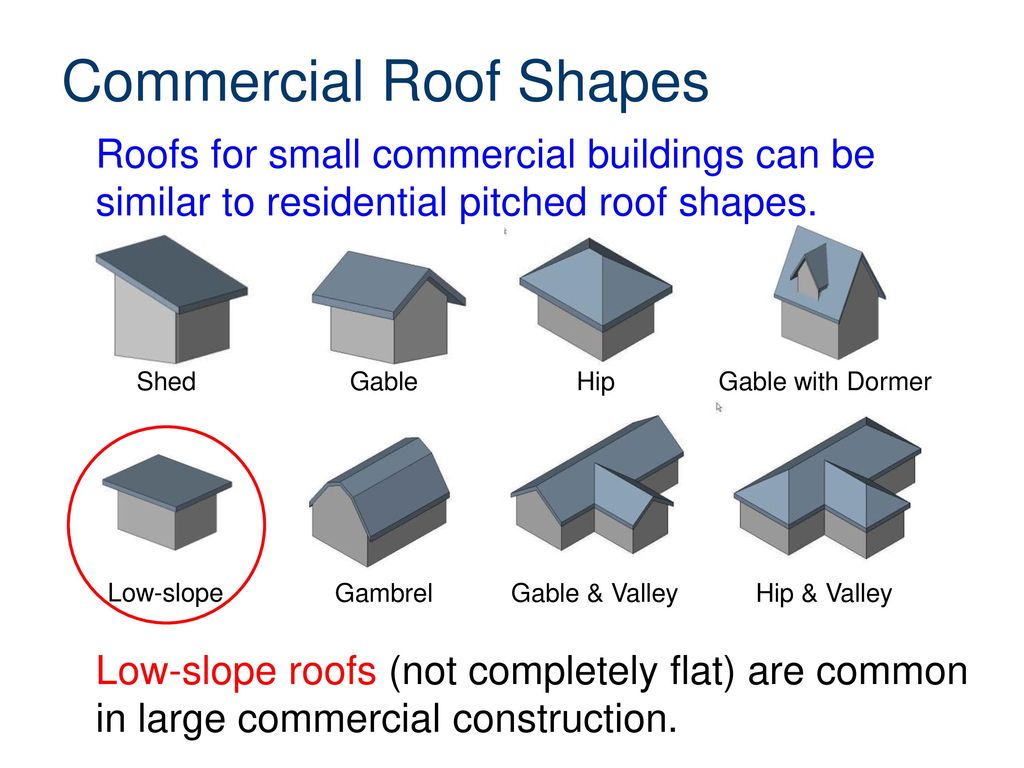

Describe the SPF roof section below for additional info on its use as a main roofing system covering. Low-Slope Roof covering Coverings The complying with membranes are normally utilized on low-slope roofs, however might additionally be utilized on steep-slope roofing systems. When used on steep-slopes, the system's fire resistance might be minimized and/or special preventative measures may be required when utilized on steep-slopes.

Nevertheless, if coverings are specified, regular recoating will certainly be required. Due to the fact that of future upkeep demands, coverings are not recommended. If a cap sheet is specified, it must be in enhancement to the 4 plies of felt. Asphalt often tends to obtain fragile with age, making it incapable to suit normal building motions.

High top quality producers very carefully check the resource of their raw asphalt as well as just how it is customized. There are three primary kinds of MB sheets, as well as field-applied modified mopping asphalt: Figure 3.

The smart Trick of Roofing Boston That Nobody is Discussing

APP polymer is mixed with asphalt and also fillers. The sheets are offered in base, interply, and also cap sheet range.

The cap sheet is either heat-welded (i. e., torched) to the base sheet, or it is stuck in cold adhesive. Mechanically attached systems are additionally readily available. Keep In Mind: APPLICATION megabytes sheets are likewise readily available with a factory-applied adhesive on the underside of the sheet, which allow them to be self-adhering. Several useful reference suppliers presented these products in the very early 2000s.

Fully adhered roofing system systems commonly have the highest wind uplift resistance and physical performance as well as are normally considered the highest carrying out technique of setup for single ply roofing systems. Figure 4. Application of a completely stuck single-ply membrane layer. Figure 5. Application of aggregate ballast over a single-ply membrane layer. The membrane layer is i thought about this loose-laid over the substrate and after that covered with ballast to withstand wind uplift.

For these reasons, fully adhered systems or mechanically affixed systems are favored over loose-laid. Figure 6. This EPDM membrane was reduced by a piece of accumulation. Setup of a stone-protection over the membrane would certainly stay clear of aggregate punctures. These kinds of slits are really hard to locate. Completion of a pen reveals the scale.

Roofing Boston for Beginners

Installation of a stone-protection over the membrane would avoid punctures as well as sharp pieces such as these. The membrane layer is loose-laid except for a distinct rows of bolts.

After installation of the membrane, a batten bar is placed over the membrane layer and screwed to the deck. Mechanically attached systems might not be appropriate for buildings in high wind zones.

To avoid tear propagation in the event that the membrane layer is torn, it is suggested that only strengthened membranes be specified for this attachment approach. Due to the mechanical anxieties focused on the edges of the sheet as well as the air pumping which acts to pull interior air into the roof covering assembly as well as create condensation problems, mechanically secured membrane layers are not typically taken into consideration the finest selection.

The attaching plates are manufacturing facility layered with the exact same product as the roof membrane and an induction welder tool is utilized to bond the roof membrane to home plates from over the membrane. The membrane is fully stuck around the you could look here roof covering boundary, but elsewhere the membrane is just loose-laid. This system must only be used over an air-impermeable roof deck or over an air obstacle.